Where: Strijp-S area, Klokgebouw | Hall 3, Klokgebouw 50 , Map No. C1 | Eindhoven, The Netherlands

When: 19-27 October 2024

What: Exhibition

Joint exhibition between Aalto University Bioinnovation Center and CHEMARTS on bio-based materials.

Can we make wood surfaces shimmer and shine or create a spray that can make textiles waterproof without using harmful chemicals? What if we were okay with imperfections in the materials we use in the future? Do we really need materials that last forever, or can we think about materials in a new way?

To make these ideas real, we need to try out new ways of thinking and creating. The exhibition at Dutch Design Week shows two different stages of creating bio-based materials. CHEMARTS focuses on experimenting with new materials, while the Bioinnovation Center works on research and more advanced projects aiming for practical use. All displayed projects are results of interdisciplinary collaboration. The Bioinnovation Center and CHEMARTS are part of Aalto University, Finland.

You can find Aalto Bioinnovation Center together with Chemarts materials Table at the Strijp-S area, Klokgebouw | Hall 3. Read more on the DDW website.

Team

Pirjo kaariainen, Curator

Anna van der Lei, Curator

Susanna Ahola, Coordinator Aalto University Bioinnovation Center

Opening times and access

The exhibition is open 11:00 – 18:00. Access with a DDW Ticket.

Aalto University Bioinnovation Center. Photo by Esa Kapila.

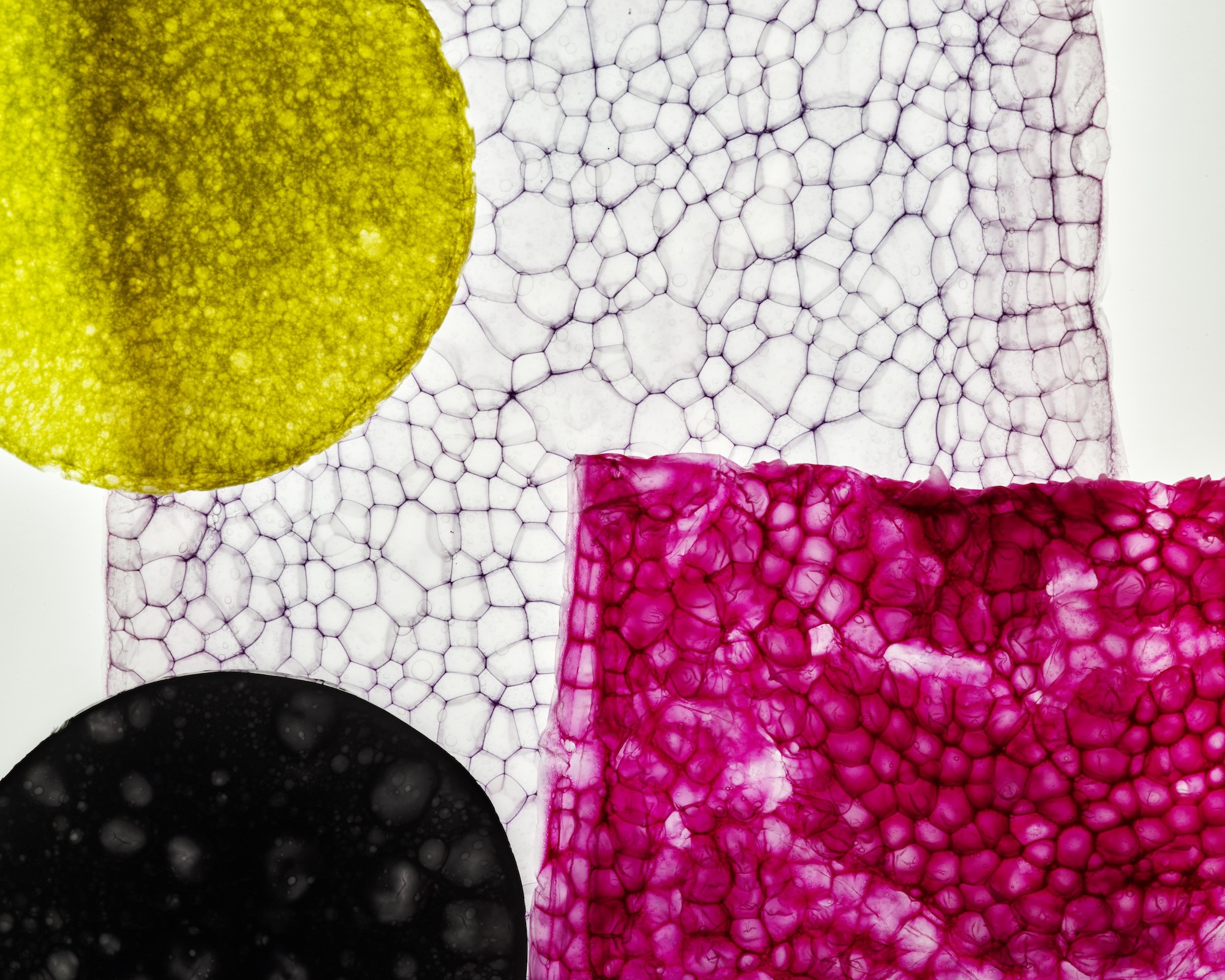

Biodegradable materials and textiles for the digital world

Doctoral researcher Sofia Guridi

Photo: Vertti Virasjoki

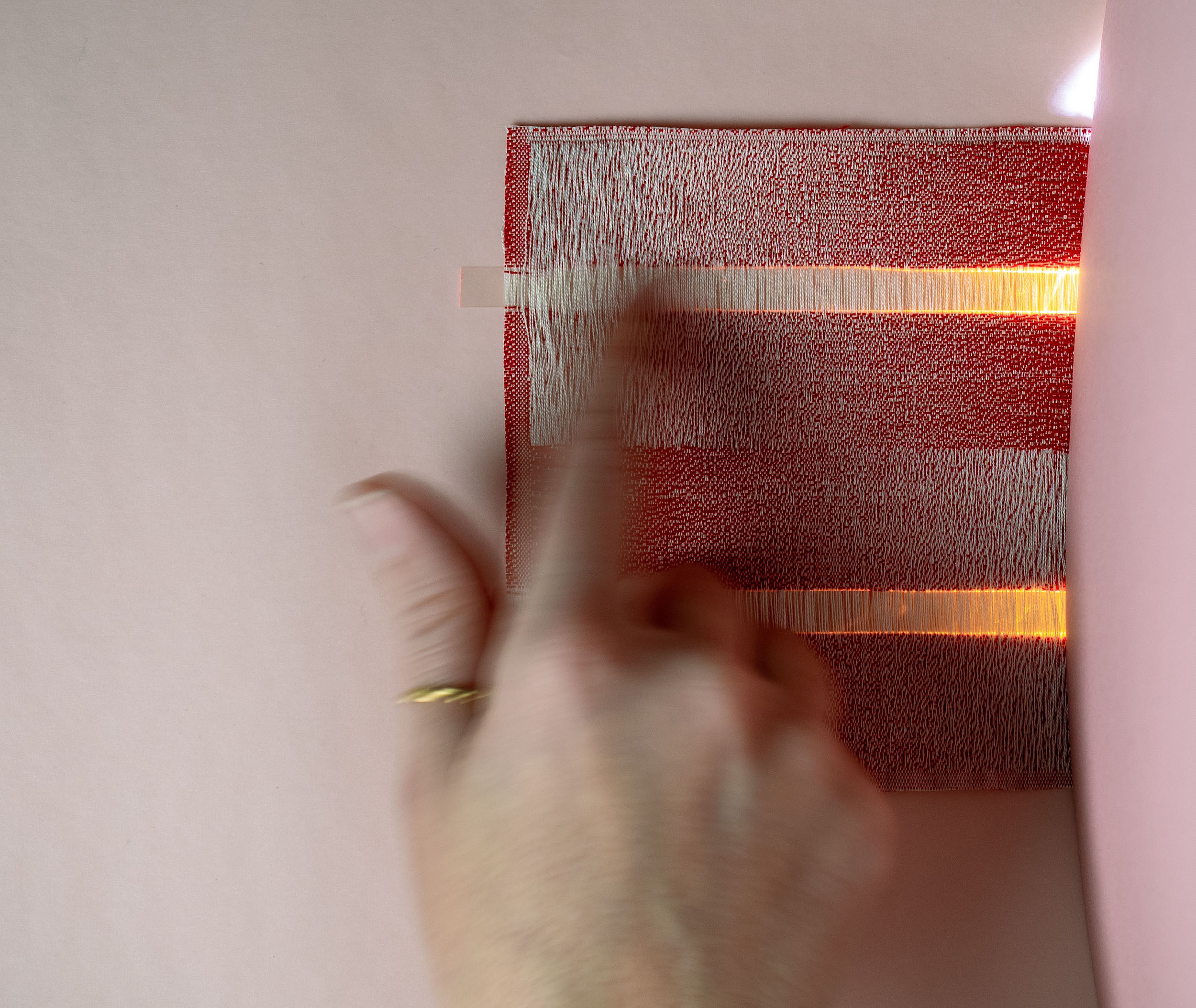

As our digital world expands, do physical interfaces always have to be rigid, made of precious metals, and everlasting? What if we could design stimulating, non-toxic, and more sustainable alternatives? We could create flexible, textured, and biodegradable interfaces that turn back into soil once they’re no longer needed.

Machine learning and artificial intelligence meet bio-based materials

Doctoral researcher Matteo Iannacchero

Photo: Aalto University/ Mikko Raskinen

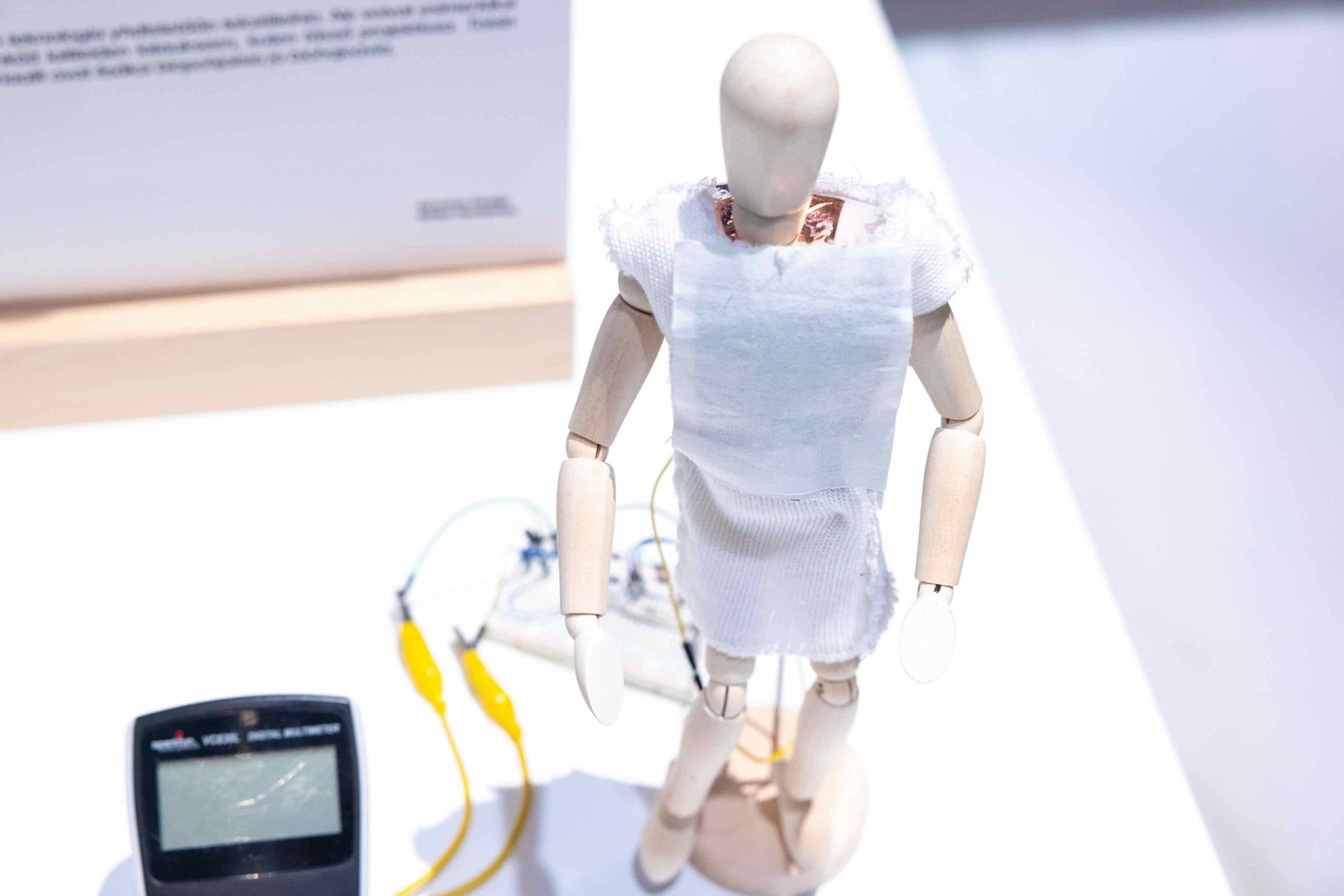

Electronic textiles (e-textiles) are fabrics enhanced with digital technology. This project aims to replace traditional metal components in e-textiles with more sustainable, flexible parts optimized via machine learning. Our innovation is a triboelectric nanogenerator (TENG) made of polylactic acid (PLA), a bio-based and biodegradable material. Developed in collaboration with Prof. Lena Kramer, this TENG generates electricity through body friction, offering a greener way to charge devices. Try scratching the doll to see the capacitor charge in real-time.

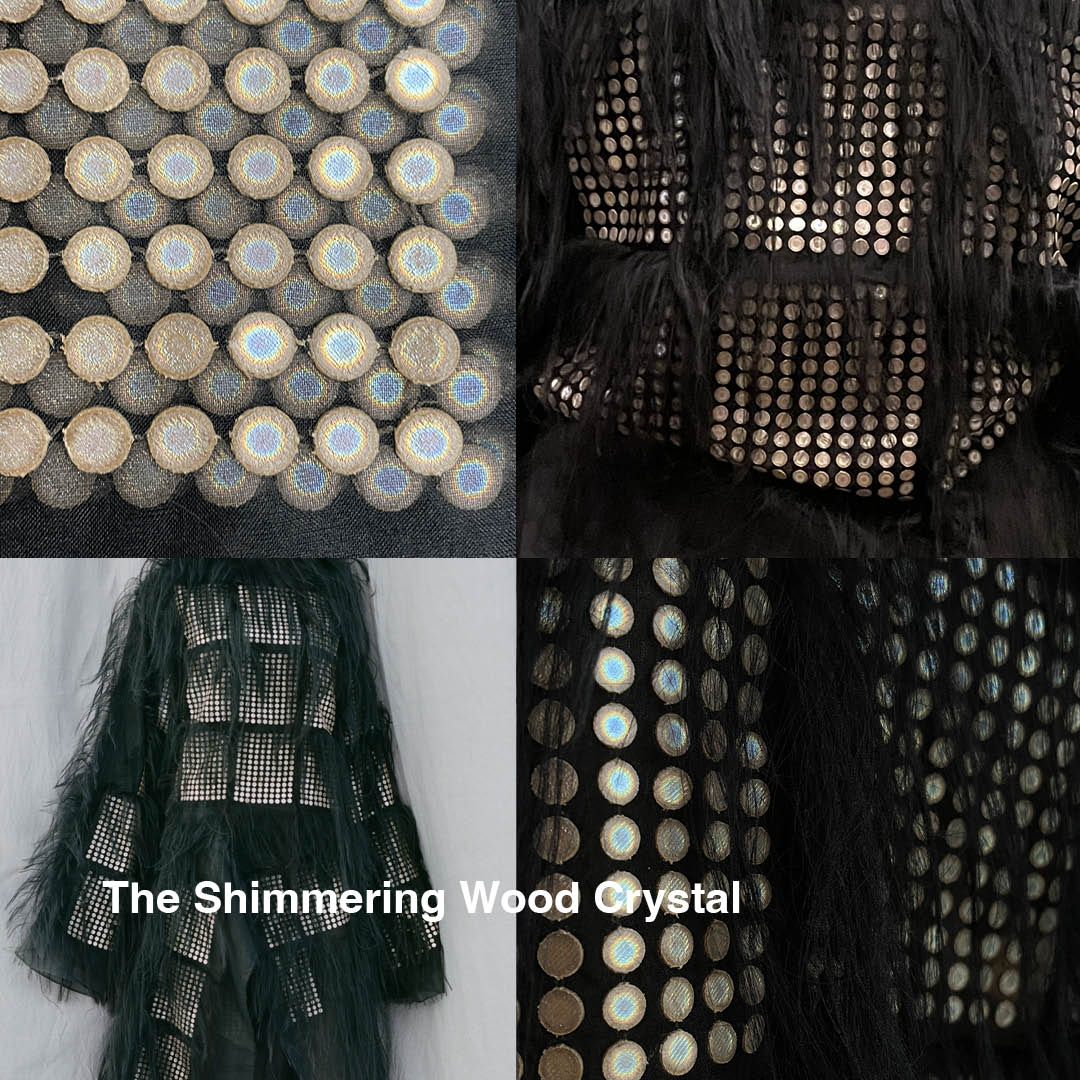

Shimmering Wood Crystals

Structural Colour Studio team: Noora Yau, Konrad Klockars and Anna Semi

https://ddw.nl/en/programme/12592/the-shimmering-wood-crystals

Delving into the ecological concerns of modern fashion, the project addresses the environmental impact of fashion embroidery, tainted by their origin in plastic and metallic effect pigments. This collaborative project redefines fashion sparkle with premium renewable materials. The wood-based crystals are crafted using 3D printing technology on silk organza and adorned with a structural layer of nanocellulose. This wood-derived color does not fade like pigments, and the final product is fully biodegradable and non-toxic, offering a revolutionary, sustainable alternative in fashion. The crystals are crafted exclusively from renewable materials and are ethically produced in Finland.

From banknotes to textiles

Researchers Inge Schlapp-Hackl (Aalto University) and Matthias Selinger (Vienna University of Technology) with project team

Photo: Aalto University/ Esa Kapila

Enormous amounts of banknotes are taken out of rotation every year, e.g. € 113 billion in the EU in 2019. The estimated lifetime of each note is around three years, after which polymer-based ones are recycled, and cotton-based ones are incinerated. This has motivated the research team to investigate the chemical recycling of cotton-based banknotes using Ioncell®, a technology developed for the sustainable production of synthetic cellulose fibres. Its green colour comes from the original colour of used banknotes.

Alternatives to fossil-based textile fibres

Doctoral researcher Helena Westerback

Photo: Aalto University/ Esa Kapila

Most of our outdoor garments rely on synthetic fabrics for water-repelling properties. Moving away from oil-based products, new solutions are needed to gradually replace most of the synthetic fibers. The CelluMimicry project aims to use biomimetic approaches to produce water-repellant cellulosic textiles. This exhibit presents materials using lignin within the textile fibres to improve the waterrepellant properties. The brown shades are the natural colour of lignin.

Bio-based coating for water repellent textiles

Doctoral researcher Sahar Babaeipour

Garments by fashion design student Riikka Kiili

Photo: Aalto University/ Esa Kapila

This research addresses the growing need for more sustainable and multifunctional textile coatings in the texIle industry. The project offers an innovative solution by using biobased nanoparticles derived from natural fatty acids and lignin. These materials form a versatile coating on fabrics, enhancing water repellency, breathability, and antibacterial properties without compromising ecological integrity. The colourful trousers are originally crafted from wood cellulose and recycled cotton, and treated with the new bio-based coating to make it both water-repellent and biodegradable.

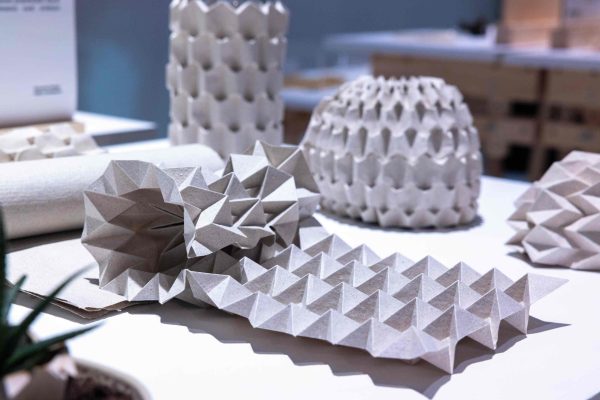

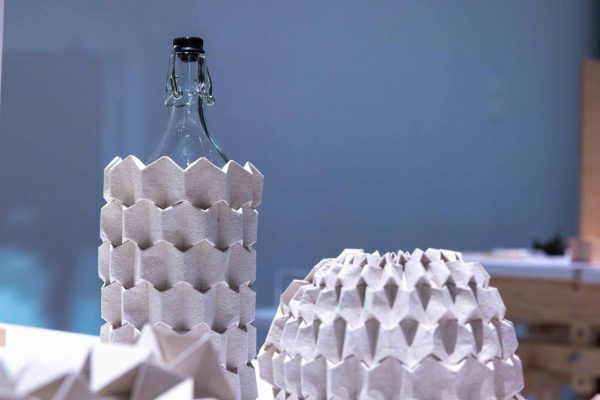

Solutions to the sustainability problems of the packaging industry

Doctoral researcher Laureen Mahler

Photo: Aalto University/ Mikko Raskinen

The interdisciplinary Cellugami project combines design and mathematics to investigate origami tessellations as a sustainable, reusable alternative to secondary packaging. This exhibit presents a series of tessellated packaging structures made from 100% nettle, a natural bast fiber. The structures are flat-foldable, dynamic, and biodegradable, thus providing a means to reimagine the aesthetics, functionality, and life cycle of packaging materials.

Tracking packages and sensing their conditions during the supply chain

Doctoral researcher Madhawa Basnayaka

Photo: Aalto University/ Mikko Raskinen

The packaging industry is a rapidly growing sector with an expected market share of ~$27 billion by 2024. As a promising actor of the sector, sustainable and intelligent packaging of products can provide not only protection against deteriorative ambient effects but also traceability and monitoring data across global supply chains. Completely bio-based chipless Radio Frequency Identification (RFID) tag is an innovative packaging solution especially for medicine, biological products and fresh produce. The project aims to study thermal, hygroscopic, or optical changes of lignocellulosic substrate which serve as the sensing element. Printed electronics are utilized to analyse these changes using RF electromagnetic waves.

Enhancing the recycling of beverage cartons

Doctoral researcher Emilia Kauppi

Photo: Aalto University/ Esa Kapila

Due to escalating environmental concerns and the imposition of stricter directives by the EU, there is increased demand for the enhancement of current recycling technologies, particularly for composite materials such as beverage cartons. Beverage cartons are made of high-quality virgin fiber and bleached chemical pulp, making it a valuable material for recycling. These cartons typically consist of approximately 75% paperboard, 20% plastics, and may contain 2-4% aluminum. The aim of this project is to investigate methods to improve the separation and recycling of the various material layers within beverage cartons. Project is an industrial collaboraIon with Stora Enso and Valmet.

Bio-based and biodegradable packaging – Bubbles with Benefits

Designers ValenIn Schwarz and Satu Paavonsalo with project team

https://ddw.nl/en/programme/12591/bubbles-with-benefits

Photo: Aalto University/ Bryan Saragosa

The global amount of plastic waste is forecasted to triple to over 1010 million tonnes by 2060. The Bubbles with Benefits research project focuses on developing sustainable packaging materials, including 100% bio-based bubble wrap and packaging foams. Made from cellulose, these materials are plastic free, non-toxic, biodegradable, and can be customised to suit any brand’s look. These new packaging solutions can help businesses reduce their carbon footprint, enhance their brand with sustainable values, and save costs by using less material without compromising production.

ChemArts student projects

Local bio-based materials for footwear

Project by Judith Sanders

Photo: Aalto University/ Rainer Paananen

Footwear researcher Judith Sanders joined the CHEMARTS summer course to continue her master’s research from the Willem de Kooning Academy in Rotterdam, exploring local bio-based materials for footwear. A significant aspect of her research was collaborating with a basketry artist using local plants. At CHEMARTS, willow bark fibers were her focus. After separation the rigid fibers were transformed into wearable shoes with the help of carboxymethyl cellulose (CMC) and glycerol. A byproduct of this process was a natural willow dye which was used to dye old white sneakers.

Algae-based wrapping

Project team: Master’s student Elizaveta Lingonberg and Professor Tapani Vuorinen

Photo: Aalto University/ Mikko Raskinen

About 430 million tonnes of plastic are globally produced annually, of which packaging material is the largest source of single-use plastic waste. Plant-based biopolymers, particularly polysaccharides, offer an alternative solution. This algae-based wrapping uses polysaccharides extracted from seaweed. Its properties vary depending on the additives used, affecting its sensitivity to moisture and water, as well as its antimicrobial and antioxidant properties.

Cellulose-based alternative for leather – UnMoo!

Project team: Master’s students Huang Xuanpu and Deborah Kumagai

Photo: Aalto University/ Rainer Paananen

As a co-product of the animal agricultural industry, leather production is linked to widespread deforestation and greenhouse gas emission. Additionally, the processing of animal leather is harmful to the environment, and most of the commercialised alternatives contain fossil-based materials. The UnMoo! project aims to address these concerns by exploring the potential of cellulosic materials as a sustainable alternative. The experimental material is composed of cotton, cellulose derivatives and natural dyes, with careful consideration of its texture, strength, flexibility, and colour.

Making use of sidestreams – The Roots

Project team: Master’s students Krista Virtanen, Saskia Helinska, Marja-Inkeri Murphy and Ilona Valovirta

Photo: Aalto University/ Bryan Saragosa

The aim of The Roots project is to reduce agricultural waste and to promote environmentally friendly practices in the fashion and materials industry. Root mats are a potential by-product of vertical wheatgrass farming. Instead of composting wheatgrass, this project makes leather-like materials from its roots. This new material experiment can be dyed using natural dyes, making it a fully biobased and biodegradable alternaIve to various everyday products for the future. It can be sewn and feels pleasant to the touch.

Using local materials: Roadside vegetation

Project by Master’s student Iines Jakovlev

Photo: Aalto University/ Bryan Saragosa

Roadside vegetation can be a large, diverse source of plant-based local materials. In Finland, roadsides are usually mown twice a summer, and studies have shown that mown vegetation should be removed to increase the biodiversity and reduce the eutrophication of the area. This experimental project explores the potential of fireweed, one of the most common plants on the roadsides. During the project, fireweed bast fibres were collected in wintertime, spun into yarn using a drop spindle, and knitted into experimental textile.

Contact

For Bioinnovation Center and CHEMARTS:

pirjo.kaariainen@aalto.fi or susanna.ahola@aalto.fi

For Shimmering Wood Crystals:

noora.yau@aalto.fi or anna.semi@aalto.fi

For Bubbles with Benefits:

satu.paavonsalo@aalto.fi or valentin.schwarz@aalto.fi